Description

Nitrocellulose Laquer: “AGED GOLD TOP”

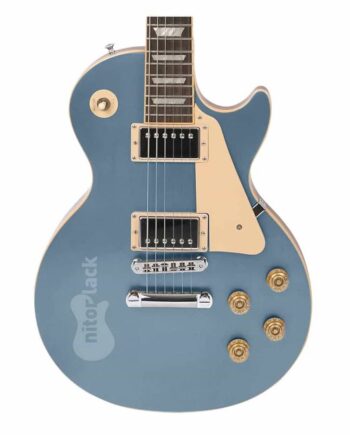

Production of the Gibson Les Paul Standard with Goldtop finish began in 1952 and continued through 1958. During this period, Les Paul Standards featured a Goldtop maple top and mahogany body. These guitars are highly valued by collectors and vintage guitar aficionados.

This color has been modified over time, deriving in two clearly differentiated tones. The „AGED GOLDTOP“ has a more aged appearance, with a darker or toasted tone.

All about Goldtop color:

The Gibson guitar in Goldtop color has been manufactured in different models and series over the years. However, one of the most emblematic models with Goldtop finish is the Gibson Les Paul Standard.

Production of the Gibson Les Paul Standard with Goldtop finish began in 1952 and continued until 1958. During this period, Les Paul Standards featured a maple top in Goldtop finish and mahogany body. These guitars are highly valued by collectors and vintage guitar aficionados.

After 1958, Gibson stopped producing Les Paul Standard with Goldtop finish and started using other finishes such as Sunburst. However, in subsequent years, Gibson has released reissues and Goldtop versions of the Les Paul Standard, including limited production models.During these years there may be differences in the color shades of the Goldtop finish of Gibson Les Pauls manufactured during these years. This is due to several factors, such as the manufacturing process, the materials used and the natural aging of the guitar. Differences between Aged goldtop and goldtop: During the early years of production of Les Paul Standard guitars with Goldtop finish (1952-1958), there were variations in color tone due to differences in the application of the varnish and the selection of the maple used in the top. Some Goldtop guitars had a lighter and brighter tone, while others could be more dark and tan or have a yellowish hue (aged).

In addition, the passage of time, exposure to light and other environmental factors can affect the tone of the Goldtop finish on a vintage guitar. Many Gibson Les Paul Standards made in that era have acquired a wear and aging pattern known as crazing that can affect the appearance of the original color.

It is important to note that, in modern reissues and current Goldtop versions, Gibson has tried to replicate the tones and characteristics of the original 1950s models. However, there may always be slight variations in color due to different manufacturing processes and the effects of artificial aging.

With the new Aged GoldTop color we wanted to replicate the more toasted and caramel goldtop tone, thus completing Gibson full range of goldtop colors.

– – – – – – – – – – – – – – – – – – – – – – – – – – –

Vintage inspired guitar colors!

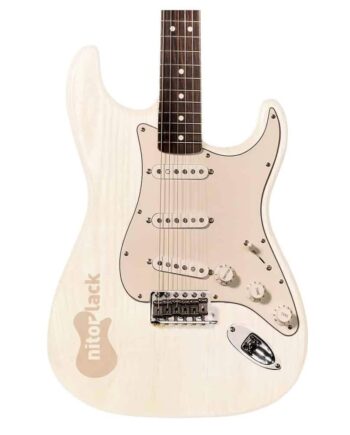

Based on original Fender and Gibson colors. To develop our guitar colors we have relied on original samples from the 50s and 60s. After great work and exhaustive study by our laboratory and technical department, some have been achieved guitar colors that faithfully recreate the tones of vintage Fender and Gibson guitars for painting electric guitar. During those years to the present, it should be borne in mind that the colors of vintage guitars have varied greatly over the years due to the aging of nitrocellulose lacquer and changes in the colors of the marks. Therefore two guitars finished in 1960 with fender colors today can be totally different from each other or from a more current guitar.

Spray Nitrocellulose Lacquer

Damit das Lackierequipment beim Lackieren deiner Gitarre kein Hindernis darstellt, gibt es von Nitorlack alle Farben auch als Nitrolack in der Sprühdose.

Paint your guitar easily with our spray. So that the painting equipment is not an impediment to painting your guitar , at Nitorlack we have developed all our guitar colors in spray format nitrocellulose . You can achieve a professional finish with our entire range of products, from backgrounds and the entire range of colors, to nitrocellulose lacquer in gloss and mate. How much product do I need to buy in spray to paint guitar ? It will depend a lot on the type of wood and the amount of product applied by each coat and the desired finish, mirror effect or “open pore” effect. But generally for painting a guitar with a medium wood pore, for an electric guitar neck: 2 spray nitrocellulose finish ( gloss or matte), for an electric guitar body: 1 spray nitrocellulose primer and 3 nitrocellulose finishing spray (gloss or matte ), classical or acoustic: 1 nitrocellulose base spray and 4 or 5 nitrocellulose finishing spray (gloss or matte) and Ukulele: 2 nitrocellulose finishing spray. (gloss or matte). If you want to apply some color, between nitrocellulose primer and nitrocellulose finish, you should add 1 or 2 spray of the guitar color desired. Spray application tips Shake vigorously between 2 to 5 minutes before applying. It is recommended to apply the spray in thin layers and with the lowest humidity possible. Apply with a uniform movement and with a distance of approximately 20 cm. It is important to apply a primer and sand 400 before applying the spray to achieve a uniform surface before coloring or finishing. Sand between hands and let dry between 12 or 24 hours between them. Apply in ventilated areas. You can buy sandpaper for guitar in our store.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Nitrocellulose guitar lacquer paint in a can

Professional finish. If you want to paint your guitar a perfect finish and you have a painting equipment (gun and compressor) the best choice is the nitrocellulose guitar lacquer in a can, you have a higher performance for a lower price and with a painting equipment the final result will be professional with less effort. It is recommended to dilute the product with solvent to adjust the viscosity and that the application is perfect, we have two types of solvents. The usual solvent used is Solvent Medium , but for more extreme humidity and temperature environmental conditions we can use Solvent Retard to avoid boiling and veiling in the finish. The optimal application conditions are between 15 and 25 ºC of temperature and 50 to 70% humidity. The dilution percentage will depend on the painting equipment and its configuration, but the recommended is between 10 and 20% solvent. The most common gun peak is 1.3 to 1.5 and the compressor pressure is about 2.5 to 3 bars.

(All informations taken from the manufacturer)